In an age of highly integrated systems, it's become more practical for consumers to discard faulty devices than repair them. Often times, you can't fix a component on the fritz and even if you could, it wouldn't be cost-effective. That's exacerbated when the component is only a small part of an embedded system. A single defective circuit could prompt you to replace your smartphone, tablet or notebook.

A team of engineers at the University of Illinois has found an approach to self-repairing circuits that could drastically reduce the waste of modern electronics. "It simplifies the system," explained chemistry professor Jeffrey Moore, a co-author of the paper. "Rather than having to build in redundancies or to build in a sensory diagnostics system, this material is designed to take care of the problem itself."

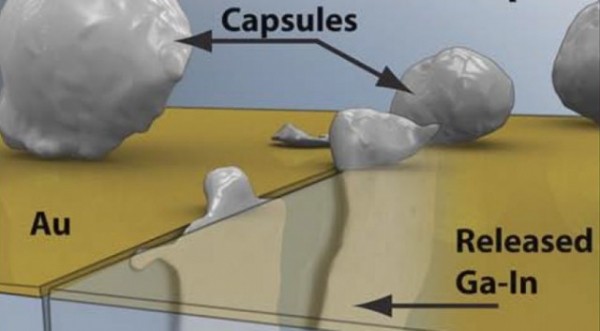

Although it seems like science fiction, the technology sounds simple: A bunch of 10-micron microcapsules of liquid metal (a gallium-indium alloy) are placed along a circuit. If the circuit cracks, the microcapsules rupture and the metal quickly fills the gap, instantly restoring up to 99% conductivity. The technology isn't perfect yet, but it works about 90% of the time – good enough for us to be excited.

Naturally, companies want you to replace your iGadget with relative frequency, so we're not sure how quickly this technology will be adopted in the consumer segment. However, the self-healing solution would probably face less opposition if it were used in consumer safety, industrial or military applications – namely automobiles, airplanes, missiles, satellites and other critical systems.