Why it matters: Silicon makes up around 28 percent of the Earth's crust by weight, making it the second-most abundant material on the planet. However, the ongoing energy crunch in China has had a huge impact on the production of high-purity silicon, sending prices through the roof in the span of just two months. This further compounds the negative effects of other material and component shortages and is similarly expected to lead to higher prices for a wide variety of consumer and industrial products.

Over the past few months, we've seen a rapid deterioration of the tech supply chain, which started with a shortage of chips and culminated with booming prices for rare earth metals and various passive electronic components. Last month, chipmakers and electronics manufacturers complained of an acute lack of skilled workers that's threatening to prolong the current situation until well into 2022, which is a sentiment shared across pretty much all industry players.

If that wasn't enough, there's a new problem looming over chipmakers – silicon, which is crucial for making everything from $1 display driver chips and microcontrollers to wafer-scale engines for machine learning, is now three times more expensive than it was a mere two months ago.

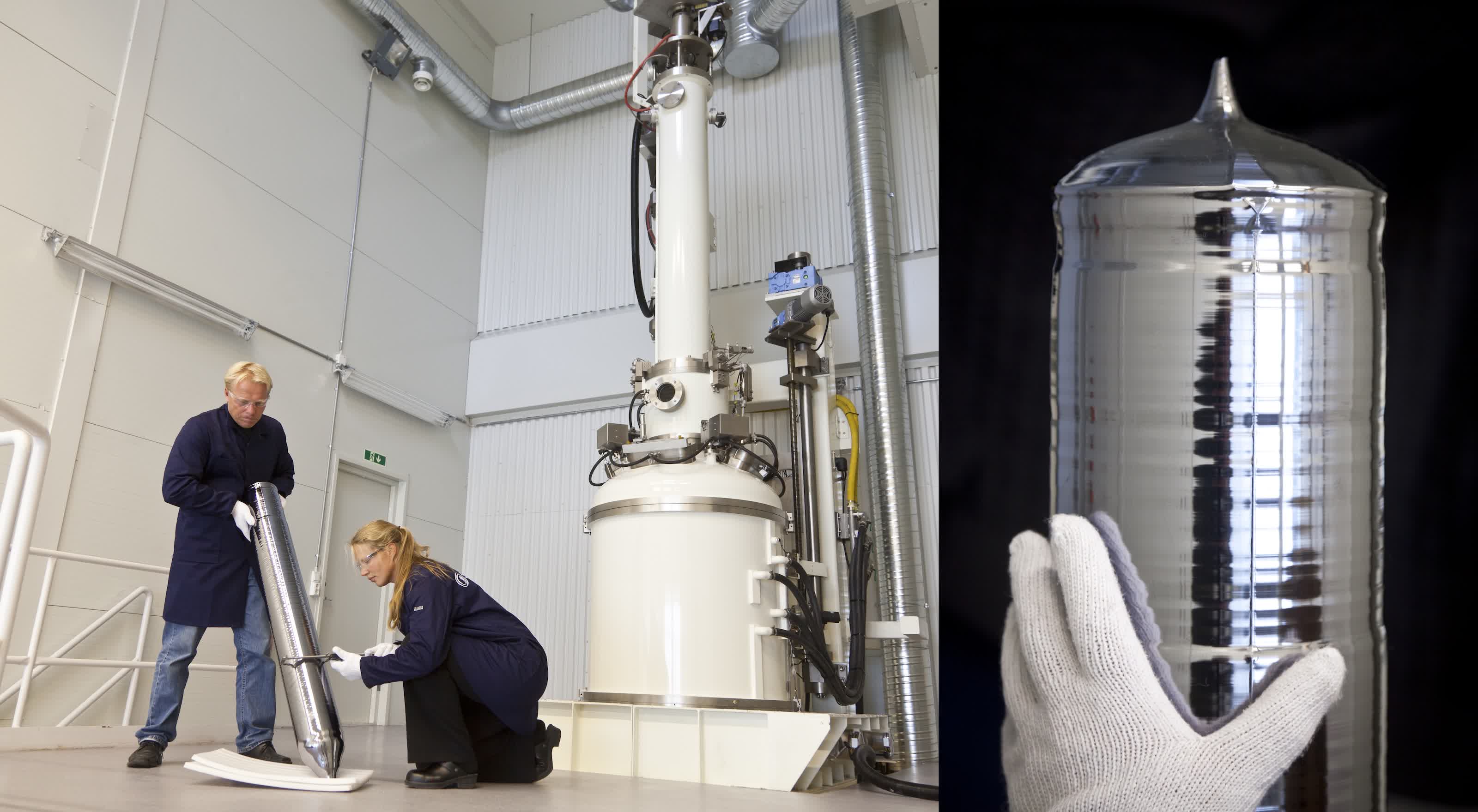

Image: Two engineers measuring a silicon ingot | Thor Nielsen

It may seem unbelievable that the world's second-most abundant element could ever become scarce, but China recently embarked on an energy crunch to reduce air pollution ahead of the upcoming Winter Olympics and boost reserves of coal and natural gas in expectation of higher energy demand during the winter months.

Production of high-purity silicon was greatly reduced as a result of the energy restrictions, to the point where some companies outside of China have had to halt their operations until they can secure a stable supply. It's expected that glass, solar panel, and car makers will see the rippling effects of this in the coming months, and manufacturers of silicone-based products are already feeling the hit on their business.

To get an idea of the severity of this issue, for the past two decades, the price of silicon has mostly hovered in the 8,000 to 17,000 yuan ($1,200 to $2,600) range per ton. Now that Chinese silicon suppliers in the Yunnan province have reduced their output by 90 percent compared to August levels, the prices have surged to as high as 67,300 yuan ($9,880) per ton.

Industry insiders believe silicon prices will remain high until at least mid-2022, when production will ramp up again. In the meantime, some manufacturers will be able to absorb the shock, while many will likely increase the price for end customers. Even Apple, who has mostly been able to navigate the ongoing supply chain woes with relative ease, is expected to feel the pressure in the coming months.

Also read: ASML's next-gen EUV machine will give Moore's Law a new lease of life

Overall, it looks like prices for everything with a chip in it will remain high for a while yet. TSMC and Samsung have both raised wafer prices this year to fund their ongoing efforts to expand their manufacturing capacity for advanced process nodes, which is threatening to send CPU and GPU prices into the stratosphere. It also doesn't help that PC gaming has become more popular than ever amid the pandemic, which means you'll more easily score a good deal on a gaming monitor than a gaming PC moving forward.