Forward-looking: Sports gear company Wilson has reinvented the basketball. It recently created a high-tech prototype that needs no air to bounce. The so-called "Airless Prototype" is the first basketball innovation since Butler University's head basketball coach, Tony Hinkle, got Spalding to start making easy-to-see orange basketballs in 1957.

Sports gear company Wilson has reinvented the basketball. It recently created a high-tech prototype that needs no air to bounce. The so-called "Airless Prototype" is the first basketball innovation since Butler University's head basketball coach, Tony Hinkle, got Spalding to start making easy-to-see orange basketballs in 1957.

For almost 40 years, Spalding provided the National Basketball Association with regulation basketballs. In 2021, that contract ended, and the NBA signed a multi-year deal with Wilson to provide official NBA balls.

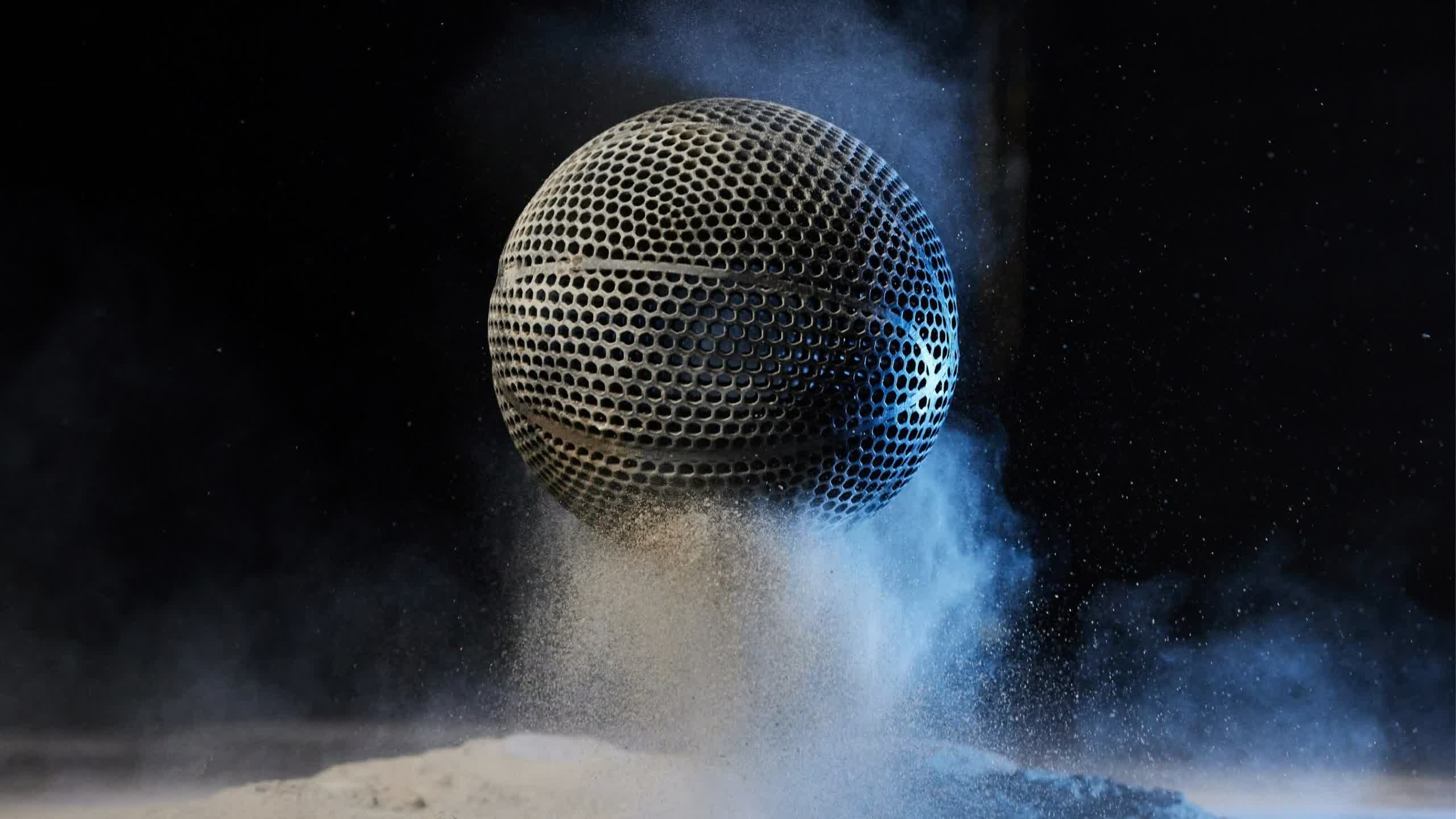

Whether it was at the behest of the NBA is unclear, but Wilson's R&D department immediately began work on developing a new type of basketball. What it came up with is a hollow honeycomb-like sphere that doesn't need inflating. While the ball has seams similar to a regulation basketball, the panels are dotted with holes.

Wilson designed the Airless Prototype on a CAD system and then translated that into a 3D-printer file. The ball needed very specific types of polymers to give it the right bounce, so it gave the file to an industrial 3D-printing outfit called EOS which usually contracts with the aerospace, automotive, and medical device industries. The company specializes in a process called additive 3D printing. This technique allows for much finer detail (above).

"Additive manufacturing was the right choice for the Airless Prototype because ... it's literally the only technology on Earth that could bring this concept to life," said EOS Business Development Director John Walker.

Unlike traditional 3D printers that stack a substance layer by layer, EOS printers lay down a dusting of powered resin and fuse it at the design points with a laser. The final processing consisted of sealing the powder, dying the white ball black, and etching the NBA and Wilson logos to its surface.

Wilson sent the Airless Prototype to its NBA test facility, which put it through "rigorous testing" to ensure its performance. The end product has nearly the same weight, size, and bounce as a properly inflated (7.5-8.5 psi) regulation NBA ball. The proof of concept then made its debut during the 2023 NBA All-Star Game's slam dunk contest introduced by Houston Rockets power forward KJ Martin (above).

Wilson's vice president of innovation, Bob Thurman, said Wilson and the NBA have no immediate plans to change current regulations to allow the use of the new ball. For now, the Airless Prototype is a one-of-a-kind that may or may not see a consumer-level release.

"This is only a dot on the development path, but we're really excited about the first step that we have here," Thurman said. "This is what we call 'The One.' You know, basically, this is like, let's make one and let people enjoy it --- and understand where we need to move forward in the future."